|

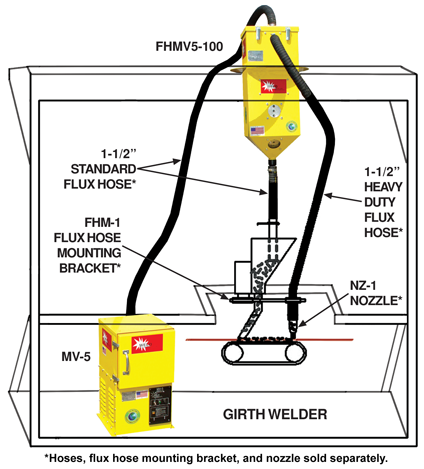

MV-5 VACUUM

- 3/4 HP

- Small, yet heavy duty electric flux vacuum.

- Very quiet. No high pitch sound.

- Works with standard 115 VAC power. Plugs into most welders (6.7 to 8 amps).

- Very low maintenance. Easy to clean out dust.

- Comes with FHMV5-100 flux hopper, 100 LB. capacity.

- Flashing light tells you when to clean.

- Shake bag, dust falls into pan, pull out dust pan and empty.

- Perfect for girth welders.

View Optional Accessories

Open Literature Page (PDF)

|

FTV-3000

- Automatic transfer valve for PFR-3000, HPFR-3000 existing and new.

- Automatically transfers flux from the upper hopper to the lower pressure tank with a push of a button on the control or remote pendant.

- Easy to install in the field on existing or factory installed on new PFR-3000 and HPFR-3000.

Open Literature Page (PDF)

|

|

DC-30 – Dust Collector

- Vacuum sensing gauge indicates when filter needs to be cleaned.

- Dirty filter is semi-automatically cleaned by high energy shock wave of air.

- Dust is automatically collected in dust drawer for easy removal.

- “Micron” cartridge dust filter is long lasting and easily replaced.

- Dust drawer holds many times more dust than a standard dust bag.

- Filter lasts much longer than a standard dust bag.

See More Information

Open Literature Page (PDF)

|

PS-7500 – Super Duty Portable Flux Recovery System

- 7.5 HP Super Duty Low Maitenance Vacuum/Blower TEFC Motor

- Vacuum sensing gauge indicates when filter needs to be cleaned.

- Dirty filter is semi-automatically cleaned by high energy shock wave of air.

- Dust is automatically collected in dust drawer for easy removal.

- “Micron” cartridge dust filter is long lasting and easily replaced.

- Super duty vacuum blower/tefc motor assembly has no “v” belts and are designed to run with low maintenance.

- Blower turns at low speed for long bearing life.

- Oil free operation unlike many competitive recovery vacuums.

- Higher vacuum and more efficient than other competitive products.

- High abrasion wear points in flux separator are inexpensive and easily replaced.

- Designed for continuous duty, high demand flux recovery applications.

- Large 150 lb. (68 kg) hopper/separator for flux storage.

- Ball valve for easy transfer of recovered flux to another container.

- Flux level windows in hopper enable easy estimate of recovered flux.

See More Information

Open Literature Page (PDF)

|

|

SPS-7500 – Super Duty Flux Recovery System

- 7.5 HP Super Duty Low Maitenance Vacuum/Blower TEFC Motor

- Comes complete with semi-automatic dust collection unit and your choice of either the fh-100 (150 lb. capacity) flux hopper/separator or the ms-1 separator at no extra cost.

- Vacuum sensing gauge indicates when filter needs to be cleaned.

- Dirty filter is semi-automatically cleaned by high energy shock wave of air.

- Dust is automatically collected in dust drawer for easy removal.

- “Micron” cartridge dust filter is long lasting and easily replaced.

- Super duty vacuum blower/tefc motor assembly has no “v” belts and are designed to run with low maintenance.

- Blower turns at low speed for long bearing life.

- Oil free operation unlike many competitive recovery vacuums.

- Higher vacuum and more efficient than other competitive products.

- High abrasion wear points in flux separator are inexpensive and easily replaced.

- Designed for continuous duty, high demand flux recovery applications.

- Large 150 lb. (68 kg) hopper/separator for flux storage.

- Slide valve for easy transfer of recovered flux to another container.

- Flux level windows in hopper enable easy estimate of recovered flux.

- Lighter and more compact than other competitive units.

See More Information

Open Literature Page (PDF)

|

Low Maintenance XP-4T

- AIR POWERED

- Lightweight and compact.

- Recycles flux dust. Does not require any emptying of the dust bag.

- Vertical dust bag allows flux dust to be recycled back into the system.

- Continuously feeds recovered flux to weld nozzle without need of any transfer valve.

- Slag is automatically removed from recovered flux.

- No moving parts in the air pump. Very efficient air pump produces higher vacuum and uses less air and is much quieter than most competitive models.

- Optional PT-100 or Heated HPT-100 100Lb. (45Kg) pressure feed tank and optional FF-3 flux feed pipe enables a continuous flux supply equal to size of feed tank [also available is the 300Lb. (136Kg) (PT-300 or Heated HPT-300), 600Lb. (272Kg) (PT-600 or Heated HPT-600), or larger pressure feed tanks.)

See More Information

Open Literature Page (PDF)

XP-4T Drawing

|

|

Auto-ReBake 850°F Super Ovens:

- HPT-100-850°

- HTS-700-850°

- 150LB. (portable) or 700LB. storage capacity.

- Designed to reduce H2O content in flux to below 0.05% by weight and thus eliminate “hydrogen assisted cracking” in high yeild steels.

- Powerful 1000 watt heating elements. (Uses specially designed elements to prevent localized overheating of flux.)

- Total and uniform heating of flux. (Heating elements extend through the flux, insuring total heat transfer.)

- Temperature range from 200°F to 850°F (93°C to 454°C).

- Accurate temperature control.

- Large thermometer indicates temperature in both °F and °C for ease of use.

- High temperature fiber glass insulation for maximum effeciency.

- Removable debris and slag screen.

- Flux valve on front of oven discharges hot flux quickly and easily into an appropriate high temperature container.

- HTP-100-850 is very portable.

- By a simple push of a button, the HTP-100-850 & HTS-700-850 rebake flux at an adjustable temperature for an adjustable time (3 min. to 5hrs., factory set at 2hrs.).

See More Information

Open HTP-100-850 Literature Page (PDF)

Open HTS-700-850 Literature Page (PDF)

|

Heated Automatic Mixing Units:

- HAMX-50

- GHAMX-150

- HPFR-HAMX-3000

- HPFR-HAMX-H150/H300

- Eliminates costly labor of manually mixing flux.

- Eliminates throwaway of unmixed recovered flux.

- Eliminates operator error in mixing the right proportions of flux.

- Increases profitability and productivity.

- Improves weld quality.

- Optional magnetic separation available.

- Gravity feed hopper/separators come in 100lb. and 300lb. total capacities (50LB. or 150LB. each side).

- Pressure feed systems come with heated 100lb., 300lb., or greater pressure feed tank.

See More Information

Open Literature Page (PDF)

Complete System Diagrams

|

|

Auto-Rebake & High Temperature Ovens:

- PFO-100-AB

- FO-700HT-AB

- FO-700HT

- 150LB. (portable) or 700LB. storage capacity.

- Powerful 1000 watt heating elements. (Uses specially designed elements to prevent localized overheating of flux.)

- Total and uniform heating of flux. (Heating elements extend through the flux, insuring total heat transfer.)

- Temperature range from 175°F to 550°F (79°C to 288°C) standard. FO-700HT-AB & FO-700HT-AB range from 300°F to 700°F (148°C to 371°C).

- Accurate temperature control.

- Large thermometer indicates temperature in both °F and °C for ease of use.

- High temperature fiber glass insulation for maximum effeciency.

- Removable debris and slag screen.

- Flux valve on front of oven discharges hot flux quickly and easily into an appropriate high temperature container.

- PFO-100 series is very portable.

- By a simple push of a button, the PFO-100-AB and FO-700HT-AB rebake flux at an adjustable temperature for an adjustable time (3 min. to 5hrs., factory set at 2hrs.).

See More Information

Open PFO-100-AB Literature Page (PDF)

Open FO-700HT-AB & FO-700HT Literature Page (PDF)

|